Timber used in making instruments is obtained through a special process.

Tone Wood

1. Material wood

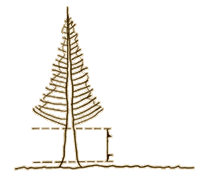

If species of trees is decided, they choose the one grown old. (In case of sound board, at least 250 years above is possible) The tree has to be straight. The part of the tree used for a instrument is above 50cm from the ground to the grown part of the first branch. After distinguishing twigs, damages by blight and harmful insects, and uniformity standard of the grain of wood, the tree is normally lumbered during the season when moisture is short that its growth stands still. (late fall through winter)

2. Material wood partition

After a tree is cut down, it is dried and shrunken with a section as the central figure. At this moment. cracking is likely to happen that a felling spot or lumber is divided into four (cleave with an axe or a wedge), prepared to process as a board and seasoned naturally for the first time.

3. Lumbering

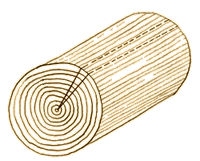

A tree is lumbered with the cleft section as the basic section. At this moment, the tree is grade (Master, AAA, AA, A) considering equality of tree color, an interval and uniformity level of an annual ring and solidity. A board lumbered after going through twice or three times of process is called Quarter-Sawned wood which must be abided by for the tree used for an instrument.

4. Air-dry

Process of air-dry is essential for wood to have excellent sound characteristics. The word ‘air-dry’ indicating here doesn’t mean dryness of moisture. The dryness of moisture gets attained to a certain degree about 2 months later after the board process. At this moment, with the board shrinking, an external measure is determined. To get the board with desirable sound characteristics, there should be enough intervals between the wood for the air to be well ventilated and also, the board should be kept for a long time(more than 3~5 years) where there are no humidity and no direct ray of light. While going through this process, other substances except for lignin in the wood, such as cellulose, oil, resin, etc. reacts with the oxygen in the air and gradually gets hardened, gets dried and finally change the nature of the wood, that is to say, the wood transformed into lighter, harder and more fragile character rather than flexible character. Thus, the materials for fine sound are ready.

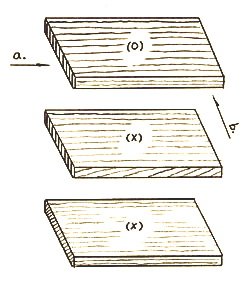

5. Reasons why Quarter Sawn is essential

a. Direction of an annual ring touches the surface of the board perpendicular. Explanation: The dark part of an annual ring is solider than the lighter part grown during the spring time. If the annual ring keeps perpendicular on the surface of the board, the most number of annual rings can be taken in per unit area. As solidity of a soundboard increases, it becomes more practicable to process the soundboard relatively thinner and to make bright and clear sound. In contrast, a weak tree has to be processed thickly which makes it impossible to expect fine sound.

b. Grain of wood is parallel with surface of a board Explanation: As it is parallel with the surface which is splitted, it is less affected by the change of humidity with the increase of solidity. (Perpendicular direction of an annual ring is sensitive to humidity) In case of a sound board, it stands well against the strong force pressured on bridge.

6. Conditions of a diaphragm in the Master grade

a. Quarter-Sawn should be completed

b. Should have dense and regular annual rings( 1cm /about 5~12 annual rings)

c. Air-dried more than five years (artificial seasoning is not suitable for diaphragm because the cell membrane is destroyed due to rapid moisture evaporation. Instead, it is used for furniture and manufacturing other wooden products)

d. Shouldn’t be bent or wrenched

7. Silky-wave

In case of a diaphragm that quarter-sawn is well organized (especially Spruce), a beautiful figure crossing an annual ring appears. (similar to a rear board of a violin) Quarter-sawn offers even aesthetic beauty with physical and acoustic excellence.